This article provides comprehensive information on diesel engine RPM gauges, including their importance, how they work, common types, installation tips, troubleshooting advice, maintenance practices, and the benefits of monitoring RPM levels.

Importance of RPM Gauges

Understanding the in diesel engines is crucial for optimizing performance and ensuring the longevity of your vehicle. These gauges provide valuable insights into the engine’s speed, allowing you to monitor and control the revolutions per minute effectively. By keeping track of RPM levels, you can prevent potential damage, improve fuel efficiency, and enhance overall engine performance. RPM gauges act as a vital tool in helping drivers make informed decisions while driving, ensuring that the engine operates within safe and efficient parameters.

How RPM Gauges Work

When it comes to understanding how RPM gauges work, it’s like having a personal translator for your diesel engine. These gauges are the storytellers of your engine’s performance, revealing the intricate dance of revolutions per minute. So, how exactly do these magical devices operate?

Imagine the RPM gauge as a diligent spy, constantly keeping an eye on the engine’s crankshaft. As the engine revs up, the gauge meticulously counts each revolution and translates it into a readable format for you. It’s like having a backstage pass to the engine’s performance, allowing you to monitor its heartbeat in real-time.

To break it down further, RPM gauges work by receiving signals from the engine’s sensors, which are then processed and displayed as RPM readings on the gauge. This seamless process ensures that you stay informed about your engine’s speed and performance at all times.

Types of RPM Gauges

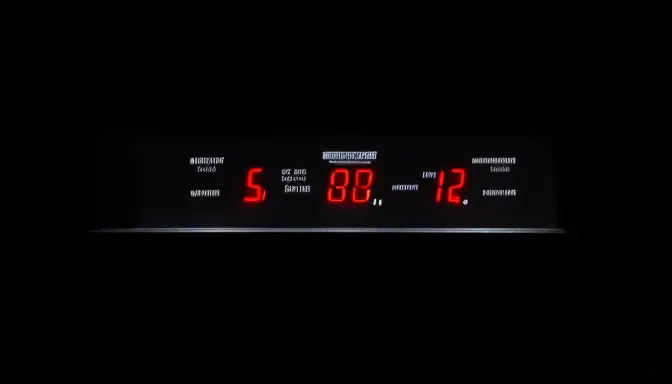

When it comes to RPM gauges for diesel engines, there are various types available to cater to different needs and preferences. Let’s explore the different types of RPM gauges commonly used:

- Analog RPM Gauges: These traditional gauges use a needle or dial to indicate the engine’s revolutions per minute. They provide a classic look and are easy to read at a glance.

- Digital RPM Gauges: Modern and high-tech, digital gauges display RPM readings digitally on a screen. They offer precise measurements and may include additional features like customizable displays.

- Single-Function Displays: These gauges focus solely on RPM readings, providing a straightforward and dedicated display for engine speed monitoring.

- Multi-Function Displays: Offering RPM readings along with other engine parameters such as temperature and pressure, these gauges provide comprehensive information in one unit.

Installation Tips

When it comes to installing RPM gauges in diesel engines, attention to detail is key. Here are some essential installation tips to ensure a smooth and successful setup:

- Prepare the Necessary Tools: Before starting the installation process, make sure you have all the required tools and equipment at hand, including wiring, connectors, mounting brackets, and a suitable gauge pod.

- Locate the Ideal Position: Choose a strategic location within the vehicle’s dashboard to mount the RPM gauge for optimal visibility and accessibility while driving.

- Secure Wiring Connections: Properly connect the wiring harness of the RPM gauge to the engine’s crankshaft sensor and power source, ensuring secure and insulated connections to prevent any electrical issues.

- Calibration Process: After installation, calibrate the RPM gauge according to the manufacturer’s instructions to ensure accurate readings and reliable performance.

- Test for Functionality: Before finalizing the installation, test the RPM gauge by revving the engine and checking if the gauge displays the correct RPM levels in real-time.

Troubleshooting RPM Gauge Issues

When it comes to troubleshooting RPM gauge issues in diesel engines, it’s essential to be thorough and systematic in your approach. Here are some common problems you may encounter with RPM gauges and effective solutions to address them:

- Inaccurate Readings: If your RPM gauge is displaying incorrect readings, it could be due to a faulty sensor or wiring issues. Check the sensor connections and wiring for any damage or loose connections. Calibration may also be necessary to ensure accurate readings.

- Erratic Needle Movement: If the RPM needle on the gauge is jumping around or behaving erratically, it could indicate a problem with the gauge itself or a loose connection. Inspect the gauge for any physical damage and ensure all connections are secure.

- Zero Reading: If the RPM gauge is showing zero readings even when the engine is running, there may be a problem with the sensor or power supply. Check the sensor’s functionality and power source to identify and rectify the issue.

- Flickering Display: A flickering or dim display on the RPM gauge could be a sign of electrical issues or a failing gauge. Verify the power supply and connections to the gauge, and consider replacing the gauge if the problem persists.

Maintenance Practices

When it comes to maintaining diesel engine RPM gauges, it is essential to follow proper practices to ensure their longevity and accuracy. Regular maintenance not only extends the lifespan of the gauges but also contributes to the overall performance of the engine. Here are some key maintenance practices to keep your RPM gauges in top condition:

- Perform regular cleaning of the gauge display to remove dust and dirt that can affect visibility and accuracy.

- Conduct calibration checks periodically to ensure that the gauge readings are precise and aligned with the engine’s actual RPM levels.

- Inspect the wiring connections for any signs of wear or damage, and repair or replace as needed to prevent electrical issues.

- Verify the functionality of the gauge by testing it under different engine load conditions to guarantee accurate readings.

By adhering to these maintenance practices, you can optimize the performance of your diesel engine RPM gauges and rely on their accurate readings to make informed decisions about your engine’s operation.

Benefits of Monitoring RPM Levels

Monitoring RPM levels in diesel engines offers a plethora of benefits that can significantly impact performance and longevity. By actively tracking and managing RPM levels, operators can:

- Prolong Engine Life: Maintaining optimal RPM levels helps reduce wear and tear on engine components, extending the lifespan of the diesel engine.

- Enhance Fuel Efficiency: Monitoring RPM levels allows for better control over fuel consumption, optimizing efficiency and reducing operational costs.

- Improve Performance: By keeping RPM levels within the recommended range, diesel engines operate more smoothly, delivering better power output and overall performance.

- Prevent Overheating: Monitoring RPM levels can help prevent the engine from overheating by ensuring proper cooling and lubrication mechanisms are functioning effectively.

- Diagnose Issues: Abnormal RPM readings can indicate underlying problems in the engine, enabling timely diagnosis and maintenance to prevent major breakdowns.

Frequently Asked Questions

- What is the purpose of an RPM gauge in a diesel engine?

The RPM gauge in a diesel engine helps monitor the engine speed, allowing drivers to optimize performance, prevent potential damage, and improve fuel efficiency by keeping track of the revolutions per minute.

- How do RPM gauges work in diesel engines?

RPM gauges in diesel engines are connected to the engine’s crankshaft and accurately display the engine’s speed in revolutions per minute. They provide real-time information on the engine’s performance, aiding in efficient operation and maintenance.

- What are the common types of RPM gauges available for diesel engines?

There are analog and digital RPM gauges, as well as single-function and multi-function displays. Each type has its own set of advantages and disadvantages, catering to different preferences and needs of diesel engine users.

- What Happened to Bluewater Yachts? The Inside Story - May 31, 2024

- Upgrade Your Boat’s Water Pump to the Mach 5 - May 30, 2024

- Upgrade Your Boat with the Big Stuff Stuffing Box - May 30, 2024